DEI Gen-3 Titanium Turbo Shields

Turbo Kooozie

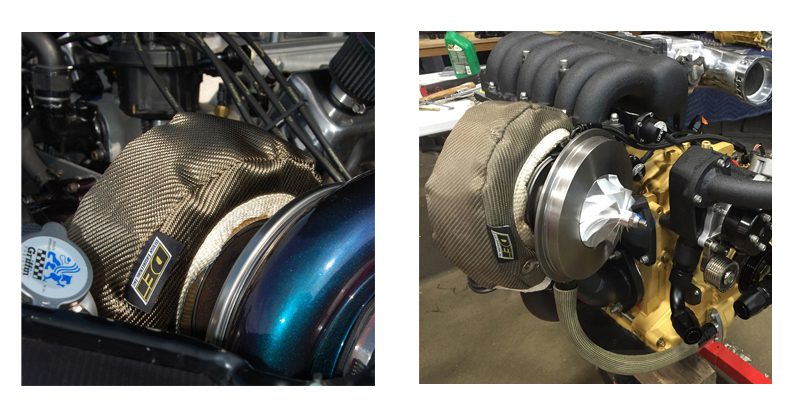

The new Gen-3 Titanium Turbo Shields from DEI were on display at SEMA 2019. Wrapping a turbo in a DEI Turbo Shield not only can reduce turbo lag, but can also prevent radiant heat from damaging surrounding components.

Turbos harness hot exhaust gases and use it to help the engine produce more power. Keeping some heat in the turbo housing is good and can help turbos spool faster. But the radiant heat from the turbo is not good, as it can start cooking nearby components, including the hood of the vehicle. DEI’s new Gen-3 Titanium Turbo Shields have been improved to better manage that “bad” heat.

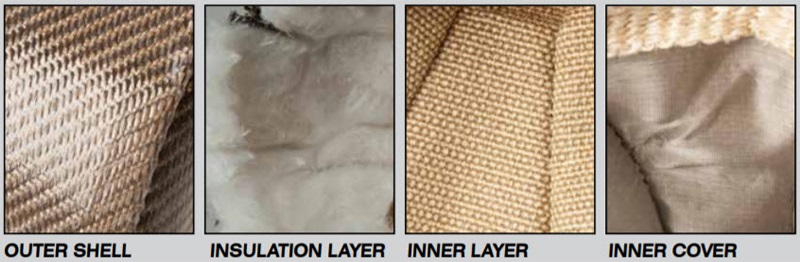

The outer layer is formed from DEI’s Titanium LR material with silicone-coated basalt, which covers the multiple inner layers of stainless steel and silica. The result is direct heat resistance up to 1,800-degrees, and radiant heat resistance up to 2,500-degrees Fahrenheit.

Here is DEI at SEMA 2019, with the new Gen-3 Titanium Turbo Shields:

DEI Gen-3 Titanium Turbo Shield at SEMA 2019

The new DEI Gen-3 Titanium Turbo Shields are available as a shield only or in a kit.

DEI Gen-3 Titanium Turbo Shield Kit Features:

• One Turbo Shield

• One 2 in. x 15 ft. roll of Titanium exhaust wrap

• Two 20 in. stainless-steel locking ties

• One 5 ft. roll of fastening wire

COMPANY DETAILS |

|

|

|

Company |

Design Engineering Inc. |

|

Website |

|

|

Connect |

|

|

Contact |

|

|

Phone |

(440) 930-7940 |

|

Address |

604 Moore Road |

|

Avon Lake, OH 44012 |

ABOUT Design Engineering Inc.®

Design Engineering (DEI), located in Avon Lake, OH, specializes in the development of thermal and acoustic performance products for the for the automotive and powersports industries. DEI also makes cryogenic intake systems and related accessories under the CryO2 brand, acoustical insulation, and sound-deadening products under the popular Boom Mat brand, as well as a full line of performance coolant additives under the brand Radiator Relief.